TriSolve Plastic Ancillary Solutions

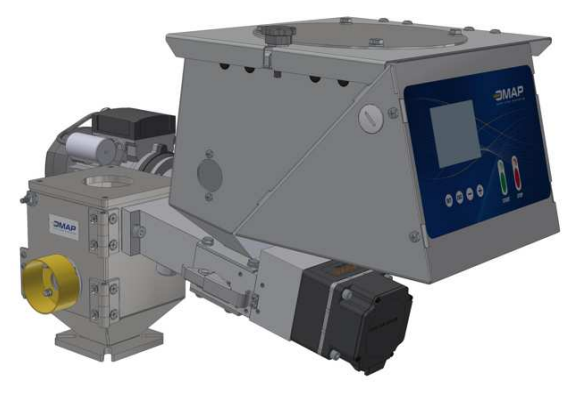

Volumetric Dosing Units – DV Series

With years of industry expertise, New Omap offers an exceptional range of volumetric dosing units designed for precision and reliability. These advanced units feature a unique tilted body and specially designed augers, ensuring accurate dosing of various materials. Constructed from high-quality AISI 304 stainless steel, the dosing unit, auger, and containment body provide the durability necessary for consistent performance in demanding environments.

The compact dimensions of the units house an extremely downsized gear motor, securely contained within a robust aluminium die-cast casing. The DV series comprises models 1 and 2, which are equipped with brushless motors that enable a wide dosing throughput range, from 0.1 kg/h to an impressive 280 kg/h. These units are perfect for handling masterbatch, additives, or other granulated materials. To enhance the volumetric dosing capabilities further, New Omap provides static TS or dynamic mixers that facilitate straightforward and efficient installation directly onto processing machines. This setup creates a complete and user-friendly dosing station, streamlining operations and improving productivity.

In addition to their robust design and functionality, the volumetric dosing units can be integrated with the Nebula interface card, which allows users to access all features and controls via the cloud. This advanced connectivity offers remote control and management capabilities, enabling real-time data collection and system integration. New Omap is proud to be among the few manufacturers offering volumetric dosing units that are genuinely 4.0 ready, ensuring that our customers are equipped for the future of manufacturing.

DV.18 Volumetric Dosing Series

The DV.18 series is equipped with a 50 W DC brushless motor that features integrated speed control, allowing for precise adjustments. With Hall effect feedback sensors, the system ensures that motor speed can be adjusted within a maximum deviation of just 0.5% of the set point, providing unmatched accuracy in dosing operations. The advanced control panel is powered by a state-of-the-art electronic microprocessor, enabling automatic operation and facilitating the use of preset operation curves. This system also supports self-configuration for new master systems, requiring minimal recalibration.

Users can store up to 50 recipes in the system, allowing for effortless switching between different materials or formulations. The dosing unit calculates screw speed automatically based on entered dosing parameters, supporting both automatic and manual operation modes, as well as injection or extrusion applications.

DV1mix Volumetric Dosing Series

The DV1mix series combines the DV1.18 volumetric dosing unit with an integrated paddle reel mixer, optimising consistency and performance in dosing applications. This combination is specifically designed to deliver the best and most constant dosing performance, ensuring that materials are mixed thoroughly before processing.

MIX Series

The MIX series paddle reel mixers are engineered to enhance the mixing of various materials while preventing stratification. These mixers are typically installed directly at the material inlet of the processing machine, significantly improving the overall efficiency of the system. Designed to accommodate up to four dosing units, the MIX series can handle capacities of up to 300 kg/h, making them ideal for high-throughput applications.

New Omap’s volumetric dosing units stand out for their precision and efficiency, making them an excellent choice for manufacturers seeking reliable material handling solutions.