TriSolve Plastic Ancillary Solutions

Central Feed System – CHS300T

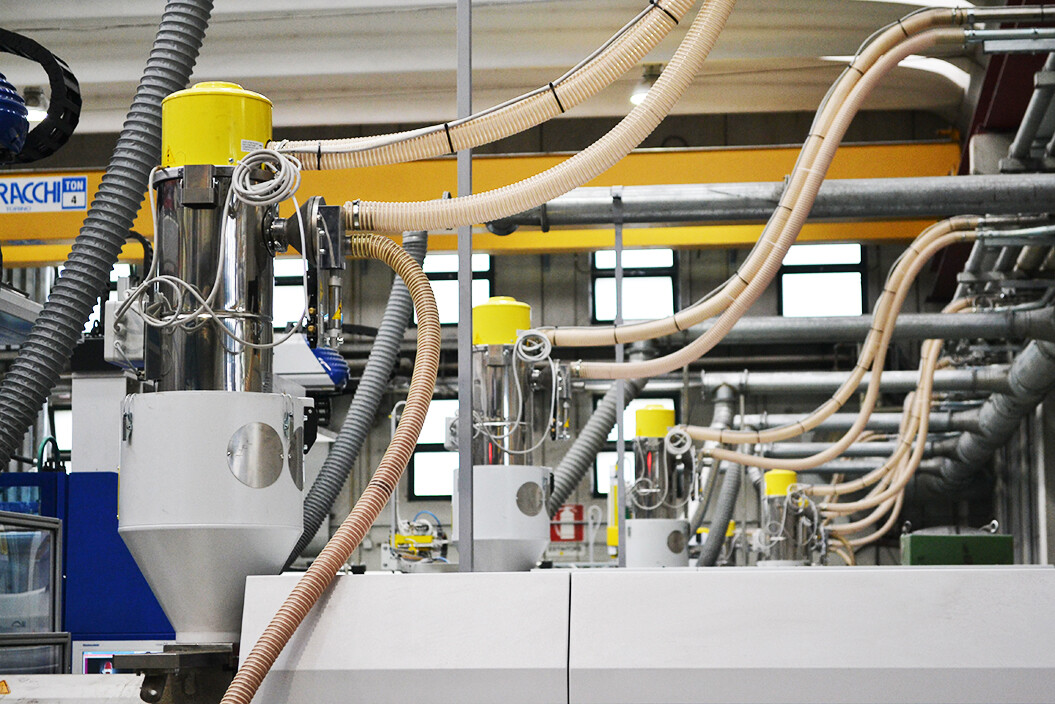

A typical central feed pneumatic conveying system comprises a vacuum blower, frequently accompanied by a backup pump on standby, as well as a primary filter equipped with automatic cleaning functions. The inclusion of a pneumatic bypass valve on the vacuum blower facilitates continuous motor operation, enhancing overall efficiency. Additionally, pipe cleaning valves are integrated into the system to purge the pipelines, which helps keep them free from stagnant material. This proactive design approach is crucial in preventing blockages, ensuring consistent feeding, and addressing issues related to the cooling of dehumidified materials.

For applications that require material drying, specific models are selected to establish closed-loop systems. This configuration effectively prevents the reabsorption of moisture within the hopper of the processing machine, thereby safeguarding the quality of the materials being processed and ensuring optimal performance.

New Omap offers vacuum material receivers made from high-quality stainless steel, all equipped with dedicated electronic cards for local parameter settings. These receivers are fully compatible with the central feed control system, CHS300T, allowing for seamless integration and interaction across the system.

The CHS300T central control system efficiently manages both material receivers and vacuum blowers, employing a “starvation” method to prioritise material requests in a sequential manner. This optimises the overall efficiency of the central feed system, ensuring that materials are delivered precisely when needed.

Furthermore, the CHS300T features a user-friendly touchscreen interface and offers various internet connectivity options. Whether through the company’s intranet or direct cloud access via Nebula, this system allows for the export of essential operational data. Additionally, it provides remote control and servicing capabilities, enabling users to effectively manage their operations from virtually anywhere, enhancing convenience and productivity.

Vacuum Blower

– Side-channel type

– From 0.85 to 11 kW

– Floor standing frame

– Electrical control box with main switch (no display nor keys)

– Filters FT, FMT, FSR

Receivers

All receivers are fitted with a metal mesh filter and a pneumatic “break-vacuum” valve for connection to the vacuum line. Pneumatic proportional ratio valves can be fitted to all models of receivers. The ratio valves have a special design with tangential closing and metal-over-metal tightening, without a gasket.

Material Receivers

– From 3 to 100 litres

– Stainless steel AISI304

– Pneumatic vacuum-breaker valve 24Vac

– Magnetic level sensor

– Mesh metal filter

– Slave control box with keypad for local parameter setting

– Alarm LED

Options

– Stand-by pumps

– Handy remote control with LCD display

– In-line cyclone filter