The Important Things to Know When Considering Cooling Towers

So, what is a Cooling Tower?

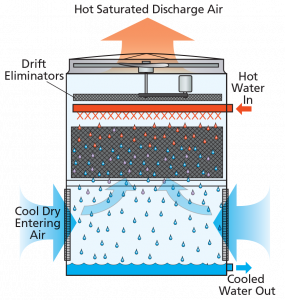

A cooling tower is a specialised heat exchanger where air and water are brought into direct contact to lower the water’s temperature. During this process, a small amount of water evaporates, which cools the remaining water circulating through the tower.

Common Cooling Tower Maintenance Problems

Maintaining cooling towers is crucial for the efficient operation of any HVAC (Heating, Ventilation, and Air Conditioning) or process cooling system. Without proper maintenance, cooling towers can develop various issues that compromise both performance and safety, including the risk of Legionella, a bacteria that can cause Legionnaires’ disease.

Cooling towers operate in an environment where air, water, heat, and chemicals interact, creating a highly corrosive atmosphere. Certain components of the tower are particularly vulnerable, especially in towers made of galvanised steel, which can experience significant wear over time.

Maintenance Issues in Cooling Towers

Buildings with cooling towers must address several challenges, not only related to the structural and mechanical aspects but also concerning water treatment. Some of the most frequent problems include:

- Corrosion

- Contamination

- Pipelines

- Scaling

These issues can significantly reduce the cooling tower’s energy efficiency, leading to increased electricity consumption and higher operational costs.

Corrosion

Corrosion is a common problem, particularly in closed-loop cooling systems that have been neglected. Air, sodium, and other chemicals in the water can corrode the tower’s materials, leading to leaks. These leaks can compromise the cooling process, especially at joints and seams, which are more susceptible to damage.

To prevent corrosion, consider using protective coatings, improving water treatment, or raising the pH to make the water more alkaline. However, it’s essential to maintain a balanced pH level, as overly alkaline water can reduce the effectiveness of chlorine treatments, which are necessary to prevent contamination, including Legionella.

Contamination

Cooling towers are naturally warm and humid environments, making them ideal breeding grounds for harmful organisms like bacteria, including Legionella. These bacteria can form biofilms on the interior surfaces of the tower, significantly reducing thermal efficiency and posing serious health risks.

Regular water testing is essential to detect contamination. If contamination is found, the system must be treated by dosing with chlorine over a 48-hour period, followed by a full flush and refill with fresh water. This process helps to eliminate bacteria and maintain a safe and efficient cooling system.

Pipelines

The pipelines connecting the cooling tower to other parts of the HVAC system are also prone to issues. Internal and external corrosion can weaken the pipes, leading to structural failures. Additionally, movement between the pipes and the tower can cause misalignments, resulting in leaks or holes.

Applying protective coatings to the piping system and ensuring all connections are secure can prevent these problems. It’s crucial that coatings are applied correctly, as poorly applied coatings are likely to fail, especially in warm, humid, or submerged conditions.

Scaling

Scaling occurs when minerals or chemicals form a thin layer on the cooling tower’s tubes, insulating them and hindering effective heat transfer. This build-up can also increase back pressure, reducing the system’s overall efficiency.

Calcium in the water is a primary cause of scaling, so regular monitoring and treatment are necessary. Applying polymer-based tube coatings can be an effective preventative measure, as they provide a heat-conductive surface that prevents calcium build-up while maintaining performance.

In severe cases of scaling, cleaning methods can be employed to remove the deposits. Following this, applying chiller tube coatings can offer long-term protection against future scaling.

By addressing these common maintenance issues, you can ensure that your cooling tower operates efficiently, safely, and with reduced risk of Legionella contamination. Regular maintenance and proper water treatment are key to extending the life of your cooling tower and keeping operational costs under control.

Cooling Tower Regulations and Legislation

Under the Notification of Cooling Towers and Evaporative Condensers Regulations 1992, it is mandatory to notify the local authority of any wet cooling towers and evaporative condensers located in their area. This requirement applies regardless of whether the local authority or the Health and Safety Executive (HSE) is responsible for enforcement.

The Regulations also stipulate that the local authority must be informed if the equipment is decommissioned. In addition to these requirements, general health and safety legislation mandates that you assess and manage the risks associated with Legionella, which can affect both employees and the public, and implement appropriate precautions.

If someone working under your control is classified as self-employed for tax and national insurance purposes, they may still be considered your employee for health and safety purposes. You are therefore responsible for ensuring their protection against health and safety risks.

If you prefer not to employ workers under these conditions, it is advisable to seek legal counsel. Ultimately, each situation must be evaluated individually, and decisions will be made based on the specific circumstances in a court of law.

Alternatives to Cooling Towers

Adiabatic coolers offer a modern and efficient alternative to traditional cooling towers, providing several advantages that can significantly reduce maintenance and operational expenses (OPEX).

Benefits of Adiabatic Coolers

- Modern and Low-Risk: Adiabatic coolers are a contemporary alternative to both hybrid and traditional cooling towers, offering reduced operational risks and improved safety. They are developed with guidance from the British Health & Safety Executive, ensuring compliance with high safety standards.

- Low Legionella Risk: These coolers have a low risk of Legionella contamination, which enhances the safety of the cooling process and reduces health concerns associated with traditional cooling towers.

- UV Sterilisation: Equipped with standard UV sterilisation, adiabatic coolers effectively manage microbial growth without the need for ongoing chemical treatments, thus eliminating the need for registration with local authorities.

- Variable Speed EC Fans: Adiabatic coolers utilise variable speed EC fan technology, which is typically 75% more energy-efficient than traditional fan systems. This not only lowers energy consumption but also contributes to reduced operational costs.

- Minimal Water Consumption: They consume less than 1% of the water used by traditional cooling towers, making them an environmentally friendly choice with significantly reduced water usage.

- Fully Built and Pre-Commissioned: Adiabatic coolers come fully assembled and pre-commissioned, minimising the installation and commissioning requirements. This results in lower initial setup costs and faster deployment.

- Minimal Maintenance: With their design optimised for efficiency and reliability, adiabatic coolers require minimal ongoing maintenance, further reducing operational costs and effort.

Adiabatic coolers provide a viable and advanced solution for cooling needs, offering improved efficiency, safety, and reduced environmental impact compared to traditional cooling towers.

Discover the Future of Cooling with TriSolve

At TriSolve, we are dedicated to delivering advanced solutions for all your cooling needs. Whether you require the dependable performance of traditional cooling towers or the modern efficiency of adiabatic coolers, our range of products and services is designed to meet the highest standards of effectiveness, safety, and sustainability.

Cooling Towers: Our cutting-edge cooling towers, available in galvanised steel, stainless steel, and GRP, are engineered to provide superior heat exchange efficiency. Featuring high-efficiency drift eliminators and contemporary heat transfer packing, our towers are built to endure the toughest conditions, ensuring reliable operation and reduced energy consumption.

Adiabatic Coolers: For a modern alternative, explore our adiabatic coolers, which offer significant advantages over traditional cooling towers. With features such as UV sterilisation, minimal water consumption, variable speed EC fans, and a low risk of Legionella, these coolers are designed for maximum efficiency with minimal maintenance and operational costs. Fully assembled and pre-commissioned, they provide a seamless, eco-friendly solution.

Maintenance and Support: We recognise the importance of maintaining peak performance and safety. Our expert team is ready to support you with comprehensive advice, regular maintenance services, and effective solutions for common issues like corrosion, contamination, scaling, and pipeline management.

Experience how TriSolve can transform your cooling system with innovative technology and exceptional service. Contact us today to learn more about our products, request a quote, or schedule a consultation. Let TriSolve help you achieve optimal performance and efficiency with our state-of-the-art cooling solutions.